Contact Us

Tel: +86-319-4508687 / +86-319-4508899

Mobile: +86-13483931539 / +86-13831925579

Fax: +86-319-4508288

Email:hongdayouzhajixie@qq.com

Address: Qian Guo Ping Industrial Zone, Nanhe County, Hebei Province

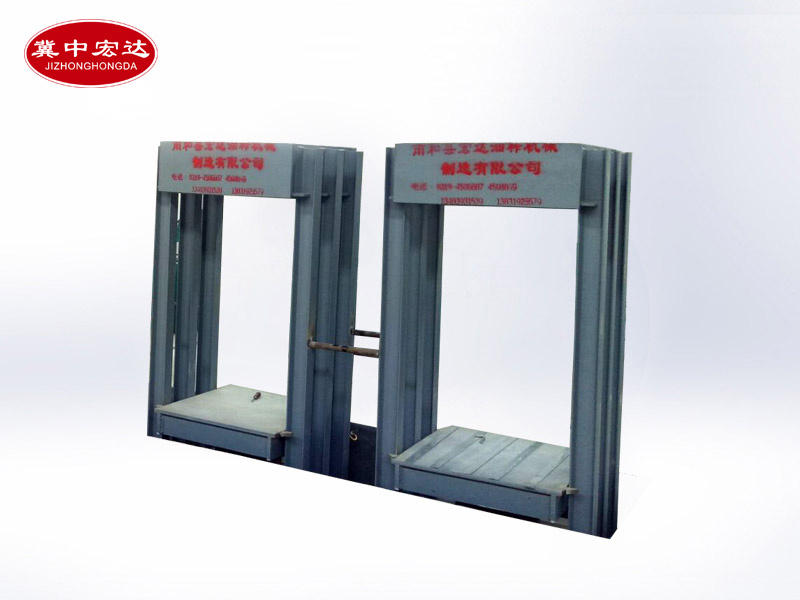

Hydraulic regeneration equipment

Keywords:

- Product Description

-

Hydraulic regeneration equipment is used to regenerate waste hydraulic oil, restoring it to performance indicators approaching or reaching those of new oil. Following is an introduction to the principles, components, types, and applications of hydraulic regeneration equipment:

Working Principle

Hydraulic regeneration equipment mainly removes impurities, water, oxidation products, and other harmful substances from waste hydraulic oil through physical and chemical methods. Common principles include filtration, adsorption, distillation, and centrifugal separation. For example, filtration uses filter screens or filter elements of different precisions to intercept solid particulate impurities in the oil; adsorption uses adsorbents such as activated carbon and clay to adsorb pigments, colloids, and some polar substances in the oil; distillation separates water and low-boiling harmful substances by evaporating them based on the different boiling points of the components in the oil; centrifugal separation uses centrifugal force to separate water and impurities from the oil.

Equipment Components

Filtering system: Usually consists of a coarse filter and a fine filter. The coarse filter intercepts larger particles of impurities, protecting downstream equipment; the fine filter removes smaller particles and different precision filter elements can be selected as needed, such as 1 micron, 3 micron, 5 micron, etc.

Adsorption system: Includes an adsorption tank containing adsorbent. When waste hydraulic oil passes through the adsorption tank, the adsorbent adsorbs impurities and harmful substances in the oil. The adsorbent needs to be replaced or regenerated periodically to ensure adsorption effect.

Distillation system: Consists of a distillation still, condenser, and cooler. The distillation still heats the waste hydraulic oil to a certain temperature, causing the water and low-boiling point impurities to evaporate. After the steam is cooled by the condenser, it becomes liquid and separates out, thus removing water and impurities.

Centrifugal separation system: Mainly consists of a centrifuge, which uses high-speed rotation to generate centrifugal force, separating oil, water, and impurities due to their different densities. The centrifuge has a good separation effect, effectively removing free water and some solid impurities from the oil.

Control system: Used to monitor and control the operating parameters of the equipment, such as temperature, pressure, and flow rate. Sensors collect data in real time, feeding information back to the controller. The controller automatically adjusts the operating status of the equipment based on the set parameters to ensure safe and stable operation.

Product Inquiry

We will contact you within one working day. Please pay attention to your email.